1. Preface

1.1. Introduction

Congratulations on your choice of instrument. It will serve you well and stay ahead of most competition for many years to come, whether in bench-top or rack system use. It gives significantly increased performance compared to traditional Timer/Counters. The ‘9X’ offers the following advantages:

- 12 digits of frequency resolution per second and 50 or 100 ps resolution, as a result of high-resolution interpolating reciprocal counting.

- A high measurement rate of up to 250k readings/s to internal memory.

- Optional oven-controlled timebase oscillators, except the CNT-91R & CNT-91R/AF, which have an ultra-stable rubidium oscillator.

- CNT-90, CNT-91(R): A variety of RF prescaler options with upper frequency limits ranging from 3 GHz to 20 GHz.

- CNT-91R/AF: Special version of CNT-91R with selected Rubidium oscillator, plus 5 Reference frequency outputs covering 100 kHz, 1 MHz, 5 MHz, and 10 MHz. Model CNT-91R/AF has a 3 GHz input C and CNT-91R/AF/20G has a 20 GHz input C as standard

- CNT-90XL: A number of microwave inputs with upper frequency limits ranging from 27 to 60 GHz.

- CNT-90(XL): Optional Pulsed RF for RF pulse characterization up to 60 GHz carrier frequency and down to 30 ns pulse width.

- Optional built-in Li-Ion battery supply realizes instant high-precision measurements in the field and true UPS operation.

- Integrated high performance GPIB interface using SCPI commands.

- A fast USB interface that replaces the traditional but slower RS-232 serial interface

- Optional external GPIB-to Ethernet controller that allows connection to LAN .

1.1.1. Powerful and Versatile Functions

A unique performance feature in your new instrument is the comprehensive arming possibilities, which allow you to characterize virtually any type of complex signal concerning frequency and time.

For instance, you can insert a delay between the external arming condition and the actual arming of the counter. Read more about Arming in Chapter 5, “Measurement Control”.

In addition to the traditional measurement functions of a timer/counter, these instruments have a multitude of other functions such as phase, duty factor, rise/fall-time and peak voltage. The counter can perform all measurement functions on both main inputs (A & B). Most measurement functions can be armed, either via one of the main inputs or via a separate arming channel (E).

By using the built-in mathematics and statistics functions, the instrument can process the measurement results on your benchtop, without the need for a controller. Math functions include inversion, scaling and offset. Statistics functions include Max, Min and Mean as well as Standard and Allan Deviation on sample sizes up to 2*109.

1.1.2. No Mistakes

You will soon find that your instrument is more or less self-explanatory with an intuitive user interface. A menu tree with few levels makes the timer/counter easy to operate. The large backlit graphic LCD is the center of information and can show you several signal parameters at the same time as well as setting status and operator messages.

Statistics based on measurement samples can easily be presented as histograms or trend plots in addition to standard numerical measurement results like max, min, mean and standard deviation.

The AUTO function triggers automatically on any input waveform. A bus-learn mode simplifies GPIB programming. With bus-learn mode, manual counter settings can be transferred to the controller for later reprogramming. There is no need to learn code and syntax for each individual counter setting if you are an occasional GPIB bus user.

1.2. Design Innovations

1.2.1. State of the Art Technology Gives Durable Use

These counters are designed for quality and durability. The design is highly integrated. The digital counting circuitry consists of just one custom-developed FPGA and a 32-bit microcontroller. The high integration and low component count reduces power consumption and results in an MTBF of 30,000 hours. Modern surface-mount technology ensures high production quality. A rugged mechanical construction, including a metal cabinet that withstands mechanical shocks and protects against EMI, is also a valuable feature.

1.2.2. High Resolution

The use of reciprocal interpolating counting in this new counter results in excellent relative resolution: 12 digits/s for all frequencies.

The measurement is synchronized with the input cycles instead of the timebase. Simultaneously with the normal “digital” counting, the counter makes analog measurements of the time between the start/stop trigger events and the next following clock pulse. This is done in four identical circuits by charging an integrating capacitor with a constant current, starting at the trigger event. Charging is stopped at the leading edge of the first following clock pulse. The stored charge in the integrating capacitor represents the time difference between the start trigger event and the leading edge of the first following clock pulse. A similar charge integration is made for the stop trigger event.

When the “digital” part of the measurement is ready, the stored charges in the capacitors are measured by means of Analog/Digital Converters.

The counter’s microprocessor calculates the result after completing all measurements, i.e. the digital time measurement and the analog interpolation measurements.

The result is that the basic “digital resolution” of + 1 clock pulse (10 ns) is reduced to 100 ps for the CNT-90 and 50 ps for the CNT-91(R).

Since the measurement is synchronized with the input signal, the resolution for frequency measurements is very high and independent of frequency.

CNT-91/91R features gap-free back-to-back frequency measurements, ensuring no missing periods The counters have 14 display digits to ensure that the display itself does not restrict the resolution.

1.3. Remote Control

This instrument is programmable via two interfaces, GPIB and USB.

The GPIB interface offers full general functionality and compliance with the latest standards in use, the IEEE 488.2 1987 for HW and the SCPI 1999 for SW.

In addition to this ‘native’ mode of operation there is also a second mode that emulates the Agilent 53131/132 command set for easy exchange of instruments in operational ATE systems. The USB interface is mainly intended for the lab environment in conjunction with the optional TimeView™ analysis software. The communication protocol is a proprietary version of SCPI.

1.3.1. Fast GPIB Bus

These counters are not only extremely powerful and versatile bench-top instruments, they also feature extraordinary bus properties.

The bus transfer rate is up to 4000 triggered measurements/s in CNT-91(R). Array measurements to the internal memory can reach 250 k measurements/s.

This very high measurement rate makes new measurements possible. For example, you can perform jitter analysis on several tens of thousands of pulse width measurements and capture them in less than a second.

An extensive Programmer’s Handbook helps you understand SCPI and counter programming.

The counter is easy to use in GPIB environments. A built-in bus-learn mode enables you to make all counter settings manually and transfer them to the controller. The response can later be used to reprogram the counter to the same settings. This eliminates the need for the occasional user to learn all individual programming codes.

Complete (manually set) counter settings can also be stored in 20 internal memory locations and can easily be recalled on a later occasion. Ten of them can be user protected.

2. Safety

2.1. Introduction

Even though we know that you are eager to get going, we urge you to take a few minutes to read through this part of the introductory chapter carefully before plugging the line connector into the wall outlet.

This instrument has been designed and tested for Measurement Category I, Pollution Degree 2, in accordance with EN/IEC 61010-1:2001 and CAN/CSA-C22.2 No. 61010-1-04 (including approval). It has been supplied in a safe condition. Study this manual thoroughly to acquire adequate knowledge of the instrument, especially the section on Safety Precautions hereafter and the section on Installation on page 1-7.

2.2. Safety Precautions

All equipment that can be connected to line power is a potential danger to life. Handling restrictions imposed on such equipment should be observed.

To ensure the correct and safe operation of the instrument, it is essential that you follow generally accepted safety procedures in addition to the safety precautions specified in this manual.

These units are designed for indoor use only.

The instrument is designed to be used by trained personnel only. Removing the cover for repair, maintenance, and adjustment of the instrument must be done by qualified personnel who are aware of the hazards involved.

The warranty commitments are rendered void if unauthorized access to the interior of the instrument has taken place during the given warranty period.

2.2.1. Caution and Warning Statements

CAUTION: Shows where incorrect procedures can cause damage to, or destruction of equipment or other property.

WARNING: Shows a potential danger that requires correct procedures or practices to prevent personal injury.

2.2.2. Symbols

Shows where the protective ground terminal is connected inside the instrument. Never remove or loosen this screw

Shows where the protective ground terminal is connected inside the instrument. Never remove or loosen this screw

This symbol is used for identifying the functional ground of an I/O signal. It is always connected to the instrument chassis.

This symbol is used for identifying the functional ground of an I/O signal. It is always connected to the instrument chassis.

Indicates that the operator should consult the manual.

Indicates that the operator should consult the manual.

One such symbol is printed on the instrument, below the A and B inputs. It points out that the damage level for the input voltage decreases from 350 Vp to 12Vrms when you switch the input impedance from 1 MΩ to 50 Ω.

2.2.3. If in Doubt about Safety

Whenever you suspect that it is unsafe to use the instrument, you must make it inoperative by doing the following:

- Disconnect the line cord

- Clearly mark the instrument to prevent its further operation

- Inform your Pendulum Instruments representative.

For example, the instrument is likely to be unsafe if it is visibly damaged.

2.2.4. Disposal of Hazardous Materials

CNT-90 & CNT-90XL only

If your instrument was ordered with a built-in battery supply (Option 23/90), it contains 12 Li-Ion cells arranged as a fixed battery pack with internal protection circuitry.

Even though this type of cell does not cause environmental damage in the same way as NiCd, for instance, you should dispose of a worn-out battery pack at an authorized recycling station or return it to Spectracom.

Individual cells cannot be replaced.

3. Unpacking

Check that the shipment is complete and that no damage has occurred during transportation. If the contents are incomplete or damaged, file a claim with the carrier immediately. Also notify your local Spectracom sales or service organization in case repair or replacement may be required.

3.1. Check List

The shipment should contain the following:

- Counter/Timer/Analyzer CNT-90/91 or Frequency Calibrator/Analyzer CNT-91R or CNT-91R/AF or Microwave Counter/Analyzer CNT-90XL

- Line cord

- Brochure with Important Information

- Certificate of Calibration

- Options you ordered should be installed. See Identification below.

- CD including the following documentation in PDF:

- Getting Started Manual

- User’s Manual

- Programmer’s Handbook

3.2. Identification

The type plate on the rear panel shows type number and serial number. See illustrations on page 2-5 and 2-6. Installed options are listed under the menu User Options – About, where you can also find information on firmware version and calibration date. See page 2-15. The CNT-91R/AF version is identified by a unique identification marking, or UID. This permanent tag contains a barcode and allows customers to track easily their inventory and property.

3.3. Installation

3.3.1. Supply Voltage

Setting

The Counter may be connected to any AC supply with a voltage rating of 90 to 265 Vrms, 45 to 440 Hz. The counter automatically adjusts itself to the input line voltage.

Fuse

The secondary supply voltages are electronically protected against overload or short circuit. The primary line voltage side is protected by a fuse located on the power supply unit. The fuse rating covers the full voltage range. Consequently, there is no need for the user to replace the fuse under any operating conditions, nor is it accessible from the outside.

CAUTION: If this fuse is blown, it is likely that the power supply is badly damaged. Do not replace the fuse. Send the counter to the local Service Center.

Removing the cover for repair, maintenance and adjustment must be done by qualified and trained personnel only, who are fully aware of the hazards involved.

The warranty commitments are rendered void if unauthorized access to the interior of the instrument has taken place during the given warranty period.

3.3.2. Battery Supply

CNT-90 & CNT-90XL only

It is possible to run the counter from an optional battery supply, Option 23/90. You must charge the battery before use or storage. The counter charges the battery automatically when connected to line power or an external DC source, whether the instrument is in standby or turned on. See the specifications for charging time in different modes of operation.

3.3.3. Grounding

Grounding faults in the line voltage supply will make any instrument connected to it dangerous. Before connecting any unit to the power line, you must make sure that the protective ground functions correctly. Only then can a unit be connected to the power line and only by using a three-wire line cord. No other method of grounding is permitted. Extension cords must always have a protective ground conductor.

CAUTION: If a unit is moved from a cold to a warm environment, condensation may cause a shock hazard. Ensure, therefore, that the grounding requirements are strictly met.

WARNING: Never interrupt the grounding cord. Any interruption of the protective ground connection inside or outside the instrument or disconnection of the protective ground terminal is likely to make the instrument dangerous.

3.3.4. Orientation and Cooling

The counter can be operated in any position desired. Make sure that the air flow through the ventilation slots at the top, and side panels is not obstructed. Leave 5 centimeters (2 inches) of space around the counter.

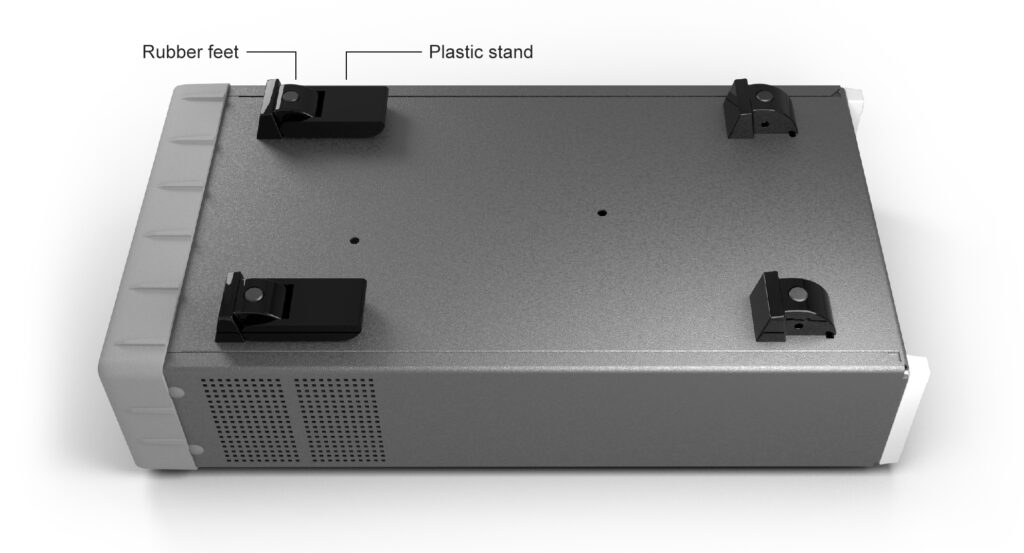

3.3.5. Fold-Down Support

For bench-top use, a fold-down support is available for use underneath the counter. This support can also be used as a handle to carry the instrument.

3.3.6. Rackmount Adapter

If you have ordered a 19-inch rack-mount kit for your instrument, it has to be assembled after delivery of the instrument. The rackmount kit consists of the following:

- 2 brackets, (short, left; long, right)

- 4 screws, M5 x 8

- 4 screws, M6 x 8

WARNING: Do not perform any internal service or adjustment of this instrument unless you are qualified to do so. Before you remove the cover, disconnect mains cord and wait for one minute. Capacitors inside the instrument can hold their charge even if the instrument has been separated from all voltage sources.

3.3.7. Assembling the Rackmount Kit (Option 22/05)

- Turn the devices upside down

- Remove the rubber feet in the plastic stand

- Loosen the screws underneath the rubber feet

- Remove the plastic stands

- Remove the four decorative plugs that cover the screw holes on the right and left side of the front panel.

Use the following steps to complete the side by side rack mount installation for your products. If necessary, refer to the item numbers in the following diagram for additional detail.

- Determine where you would like each unit positioned (i.e., on the right or left side)

- If plugs exist on the mounting holes on the front left and right side of product cover, remove and discard them

- Using screwdriver, screw the rack ear (Item #2) into place using the supplied 10mm screws (Item #5)

- Pinch the hinge pins together to separate the right and left hinge halves (Items #3 and 4)

- Attach hinge halves to the unit with hinge facing towards the front (as displayed in diagram)

- Using a screwdriver, remove the existing rear brackets on the back of each unit

- Using existing machine screws removed in previous steps, attach the rear brackets supplied with the mounting kit (Item #1)

- Pinch the hinge pins together into the stored position. Align the hinge halves together between the two units, and swing together side by side. The hinge pins should snap into place securing the front of the two units together

- Take the supplied Hex Spacer (Item #7) and place between middle rear brackets, and secure using the supplied 8mm screws (Item #6)

- Assembly is now ready for installation into standard 19” rack